News

Harben Jump Jet – A Short Story About a Long Pipe

PIPE CLEANING & DE-SILTING

If you don’t work in the sewerage industry you probably think a jump jet is a type of aircraft and you’d be right. But for those of us who make a living nearer the ground you also know it is a very useful addition to a drain jetting unit.

When trailer jetters hit the market back in the 1970’s they undoubtedly caused a revolution in the drain cleaning industry. Before the arrival of trailers, the jetters were mounted on large trucks with heavy pumps using lots of water at high pressure. Although these worked well they were expensive and the high cost stopped smaller companies breaking into the drain cleaning market.

The first Harben trailer jetter launched in 1971 changed all this. It produced 2000 psi @ 7 gpm which was enough to clean a 4″ pipe and pull about 130 ft. The pressure was quite high (for those days) and it went some way to compensating for the low flow but there was always going to be a limit to the amount of thrust these small machines could generate. As high pressure drain jetting became more widespread so too did the need to travel farther up the pipe so Bernard Hart, founder of Harben and an aircraft engineer by training, set about the task.

He had noticed when the Harben jetter was running out of water the hose began to pulse and at the same time it travelled more quickly into the pipe. Of course when the water ran out completely the hose stopped moving but it had started Bernard thinking.

Less water should mean less thrust and yet the hose moved faster!

Bernard experimented with the Harben pump, at first utilising its unique ability to run dry without damage. Sure enough starving the pump of water created a pulse in the hose causing it to jump” farther up the pipe. On inspection he found as the hose pulsed it momentarily changed in length – growing longer as the pressure dropped and shortening again when it rose. The phenomena is common in most hydraulic hoses and system designers try to control it but in drain cleaning, where the hose is laying on the base of the drain, it turned out to have a very useful side effect – it reduced friction!

Friction is the enemy of all drain jetters. On short runs when a drain jet pulls the hose into a pipe it will continue to do so until it reaches an immovable object, that’s obvious. But when a pipe is clear and the blockage is 250 ft. or more from the manhole it is the friction of the jetting hose that eventually brings forward motion to a halt. The thrust generated by the drain jet cannot overcome the friction of the hose dragging along behind it. Reduce this friction and ”Hey Presto!” the jet begins its forward journey once again.

Obviously it isn’t practical to continuously run your jetter out of water so Bernard set about finding a method that allowed the pulse to be created only when the operator wanted it. High pressure pumps are designed to run smoothly and the high speed Harben® is smoothest of them all but with the addition of a simple one-way valve and some clever engineering Bernard found he could make the Harben ”miss a beat” and in doing so create a pulse in the high pressure hose at the flick of a lever – the Jump Jet was born!

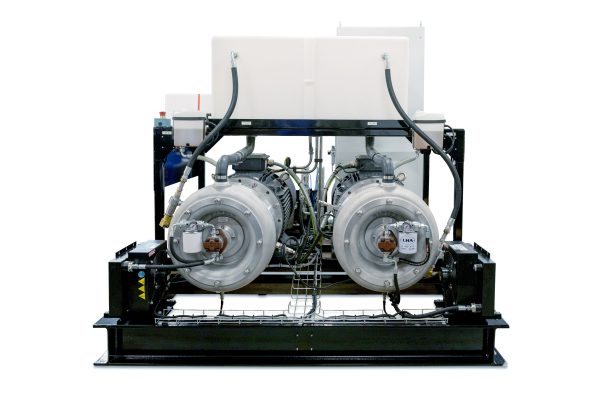

Whilst others have tried to emulate the pulse of a Harben jump jet no one has succeeded and after 40 years it still reigns supreme in the world of long run pipe cleaning. Duct de-silting contractors, many running machines for hundreds of hours each year, rely on their Harben pumps to get the job done, often pulling in excess of 650 ft. using just 11 gpm. So far the longest run reported from a single entry point is 1500 ft. and whilst this is truly exceptional it shows what these machines can achieve in the right hands.

If you want to see the Harben Jump Jet in action on your site, please contact usand we will be happy to arrange a demonstration.