News

Time to Winterize your high pressure water jetter!

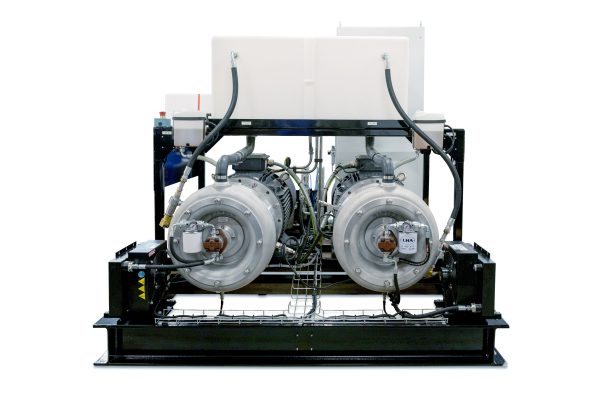

October is here and with it comes cooler temperatures. This is the perfect time to make sure your jetter is in top performance and to start preparing for the winter months. With this in mind, Harben would like to remind you of the importance of winterizing your machine when not in use. Unlike other high pressure water jetters the Harben line of radial piston diaphragm pumps can be frozen without damage. However, it is recommended that you winterize your system to ensure you’re up and running the entire winter season. If you forget to winterize your pump or are not sure that it may be frozen, always thaw it out prior to starting. Below are the winterizing and de-winterizing procedures for your Harben jetter.

WINTERIZING AND DE-WINTERIZING PROCEDURES Never start the unit if the pump is frozen

Take the following steps for winterizing and de-winterizing a Harben High Pressure Water Jet equipped with an antifreeze system.

WINTERIZING

- Remove cap from antifreeze tank

- Turn jet off

- Close valve to water tank on suction line

- Open drain valve and drain water tank

- Open antifreeze tank valve

- Connect jetting hose to recirculation line

- Turn 2-way valve at rear of unit to the vertical (up and down) position

- Turn jump jet valve (if unit is equipped with jump jet) off

- Turn pressure selector valve to high pressure (on)

- Turn jet on

- When one of the clear braided hoses connected at the top, on the back portion of water tank, behind the fuel tank, turns green, the jetting unit should be turned off

- Turn pressure selector valve to return to tank (dump position)

- Turn jump jet valve on

- Turn jet on and count to three (3)

- Turn jet off – the second braided line at top of water tank should be green

- When jet is drained shut drain valve

- With antifreeze valve open turn on then off (suction line) water tank valve allowing some antifreeze to enter suction line

- Open then close drain valve allowing antifreeze to enter ball area of valve

- Leave drain valve open for completion of draining Re-install cap on antifreeze tank

DEWINTERIZING

- Remove cap from antifreeze tank

- Turn jet off

- Shut valve to antifreeze tank

- Shut water tank drain valve

- Fill water tank

- Open inlet water valve on line going to the water pump (suction line) 6 Connect jetting hose to re-circulation line fitting below hose reel

- Turn 2-way valve below hose reel to the horizontal position (pointing towards tanks)

- Turn jump jet valve off (if unit is equipped)

- Turn pressure selector to high pressure (on)

- Turn jet on

- When antifreeze tank is full turn jet off

- Return selector valve to dump position and 2-way valve to the vertical position. Re-install cap on antifreeze tank

* INSPECT ANTIFREEZE FOR PROPER MIXTURE ON A REGULAR BASES. SOLUTION WILL BE DILUTED WITH EACH USAGE.

COLD WEATHER OPERATION

Never start or operate unit if the water pump is frozen

The following steps should be followed during cold weather operation of the unit. During transit maintain water flow to the water lines to prevent freezing of the pump and water lines. Some temperatures may be too low to allow for operation of the unit.

- Connect jetting hose to the recirculation line fitting

- Ensure that the handle on the ball valve on the recirculation line fitting is in the vertical position

- Turn jump jet valve (if unit is equipped with jump jet) on

- Turn water selector valve to the center position (handle at noon)

- Turn jet on

- Turn engine on to idle. Note, in colder temperatures, it may be necessary to turn the rpm to a higher idle to allow the water to re-circulate at a faster rate.

If you should have any questions regarding these procedures or any other maintenance issues, please call your nearest Harben representative or Harben direct.