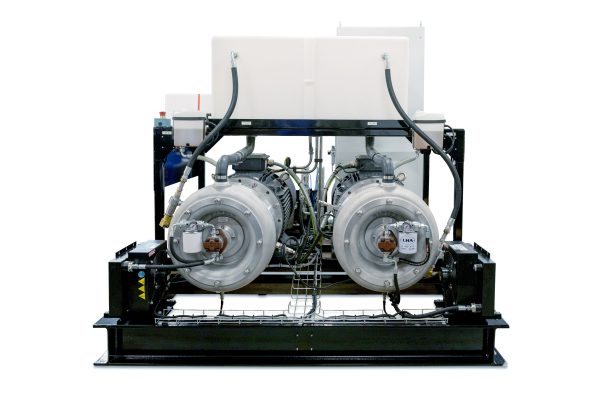

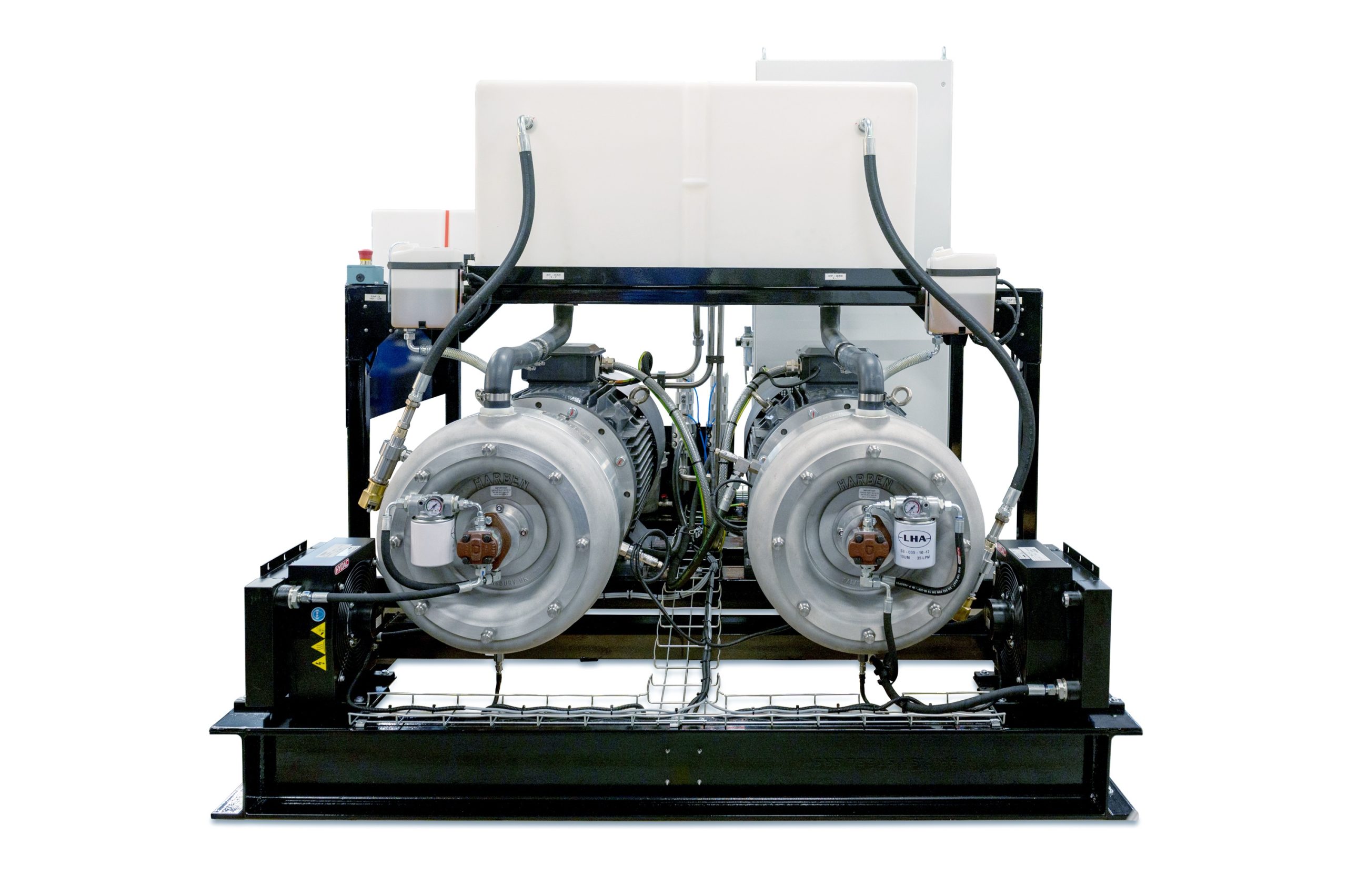

Electric Trolley Mount Jetters

- Harben ‘Century’ type pump – radial piston design to 10k psi

- Aqua Triplex pump – to 15k psi

- Safe and hazardous area operation available

- Pressure and flows up to 10,000 psi and up to 40 gpm

- Powder coated frame

- Heavy duty 3/16” steel tubing (frame)

- UV protected polyethylene tanks

- Various water capacities available

Description

Harben electric trolley mount jetters are highly versatile high pressure water jetting units. They are powered by the unique Harben high pressure diaphragm pump which is tolerant of poor quality water and has run dry capability. It can pump sea water, sub-sea control fluids and many low vicosity fluids that present pumping problems for traditional plunger pumps. No other high pressure pump offers such consistent reliability over so many fluid mediums.

Our electric trolley mount jetters are used for numerous industrial cleaning and pumping applications including:

- Surface preparation

- Heat exchanger cleaning

- Demin water pumping

- Water hydraulic systems

- Tank cleaning

- Coke oven door cleaning

- Pipe cleaning

- Umbilical flushing

- Drain jetting

We manufacture a range of standard and bespoke machines with flows up to 40 gpm and pressures up to 15,000 psi. Typically, motor sizes range from 30 to 150 hp and motor control systems can be simple start/stop panels or HMI’s and all the way up to fully integrated PLC’s. Certificated welding, lifting eyes and forklift pockets can be incorporated if required and full or partial crash frames can be supplied. Units can be specified as open, sound damped or fully silenced.

Harben jetters can be designed in accordance with most internationally recognised standards. These include NEMA hazardous and non-hazardous areas, ATEX 2014/34 EU and BS EN 1829.

- Harben ‘Century’ type pump – radial piston design to 10k psi

- Aqua Triplex pump – to 15k psi

- Safe and hazardous area operation available

- Pressure and flows up to 10,000 psi and up to 40 gpm

- Powder coated frame

- Heavy duty 3/16” steel tubing (frame)

- UV protected polyethylene tanks

- Various water capacities available

- Lowest operation and maintenance costs in the industry

- Anti-freeze recirculation system

- Various sizes of water tanks

- 10 or 15K Dump gun (Wash-down gun)

- Foot control valve

- Hose rack or manually wound high pressure reel

- Total Length Varies

- Width Varies

- Height Varies