Heat Exchanger Cleaning

Why carry out heat exchanger cleaning?

Routine heat exchanger cleaning plays a crucial role in improving productivity, minimizing downtime, and averting premature equipment failure.

A heat exchanger is a device often found in various industrial settings and manufacturing facilities, and used in facilitating the transfer of heat between two distinct mediums.

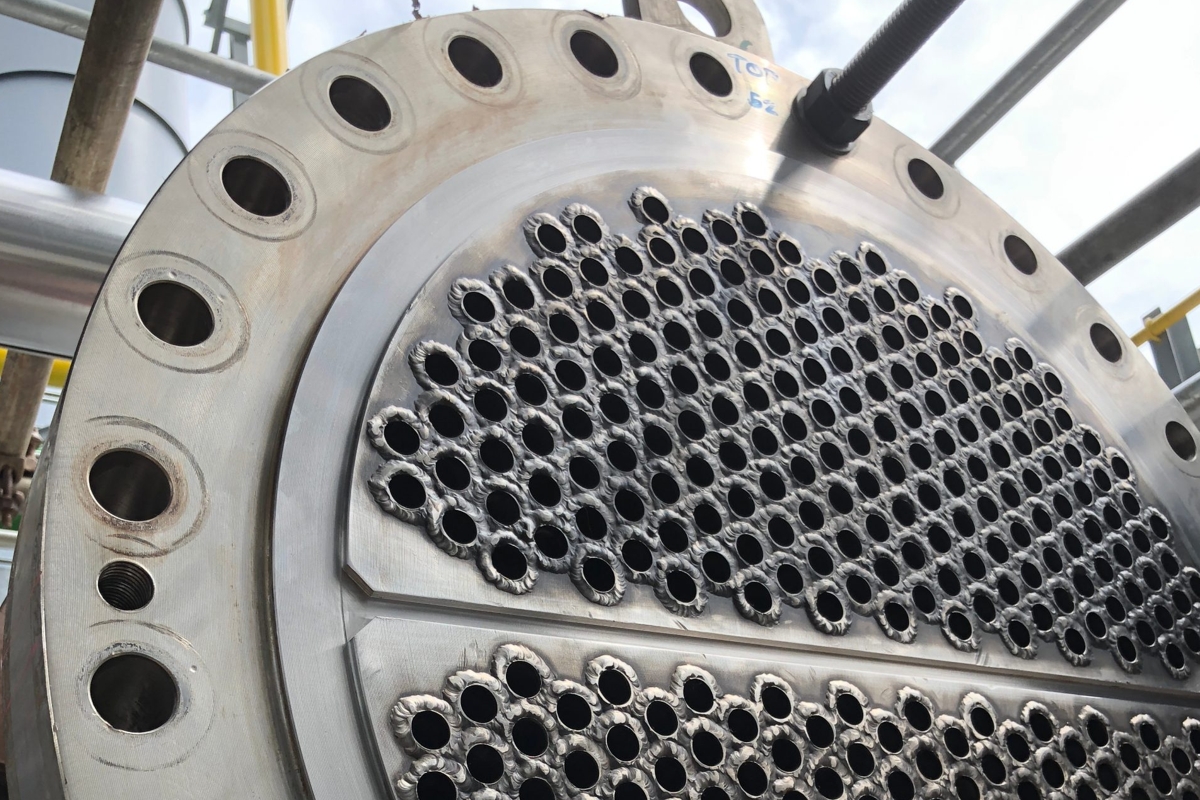

Typically, a heat exchanger features a configuration where a fluid traverses through a network of small tubes, forming a tube bundle enclosed within a sizable metal shell. A secondary fluid circulates through the shell, moving in the opposite direction, thereby facilitating the exchange of heat across the tube surfaces. Maintaining optimal flow and heat transfer necessitates meticulous upkeep to ensure the interior diameter of the tubes remains unobstructed and free from any debris or buildup.

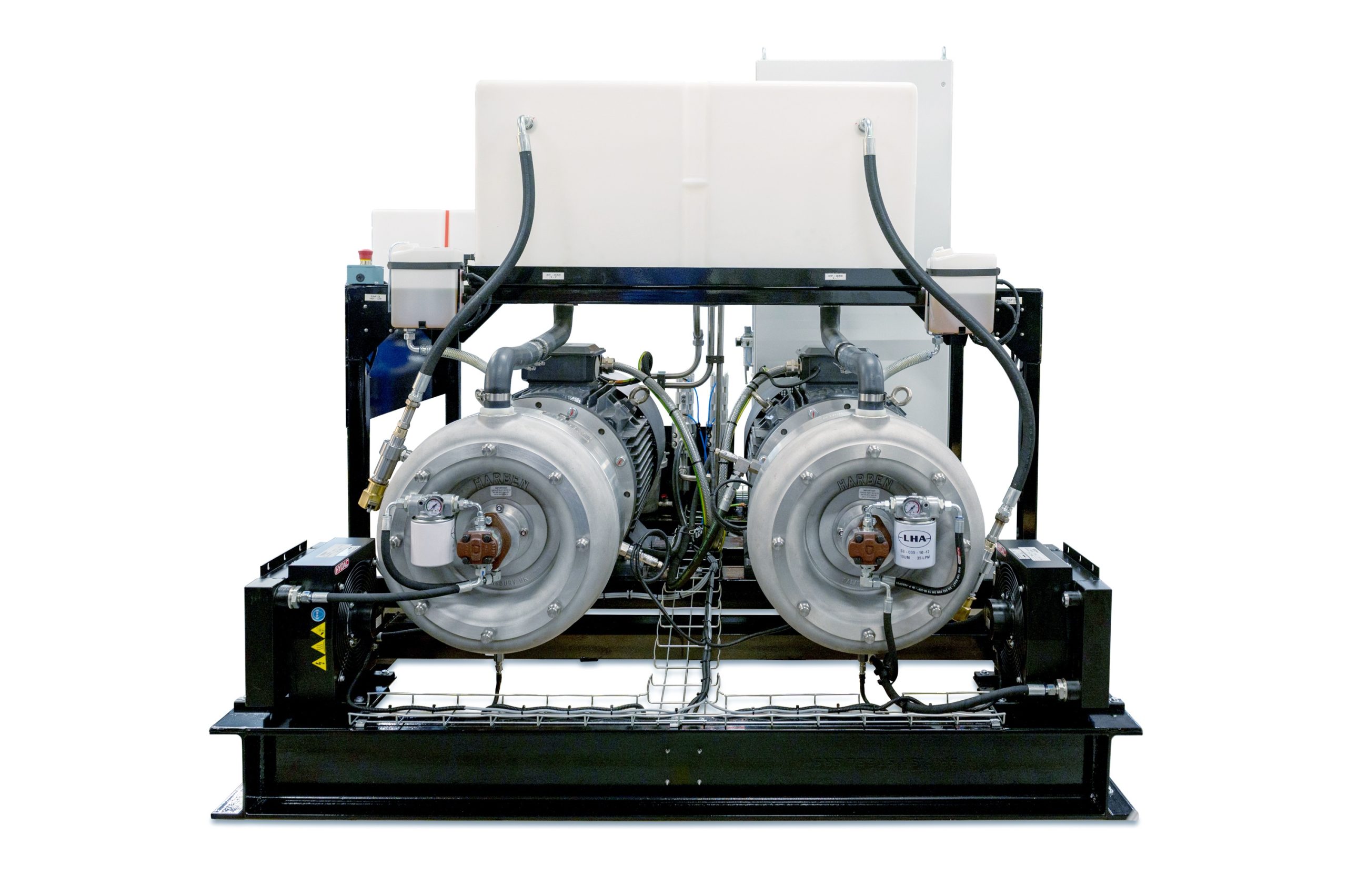

High-pressure water jetting stands as a secure and environmentally responsible approach to tube cleaning, eliminating the necessity for chemical agents. Operating within the range of 5,000 psi, water jetting proves exceptionally efficient in swiftly and thoroughly cleansing the interior of tubes.

The process involves affixing a small-diameter nozzle to either a rigid or flexible lance, which is subsequently inserted into the tube. The forceful impact of the high-pressure water jets against the tube walls effectively dislodges deposits, such as scale and rust, which are then effortlessly rinsed away with the water flow.

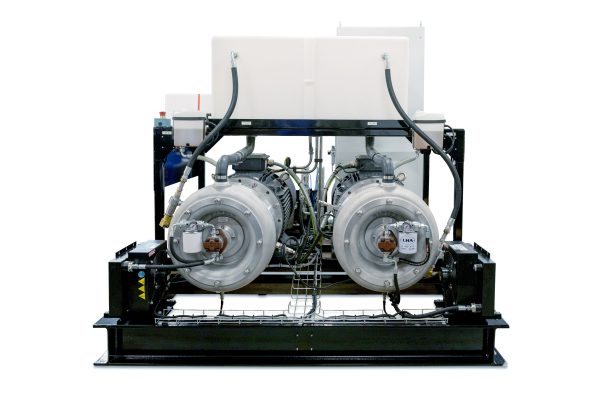

Harben specializes in manufacturing industrial-grade water jetters tailored specifically for heat exchanger cleaning applications, ensuring optimal performance and reliability in maintaining critical equipment.