Built to Outlast.

Engineered to Outperform.

Built to Outlast.

Engineered to Outperform.

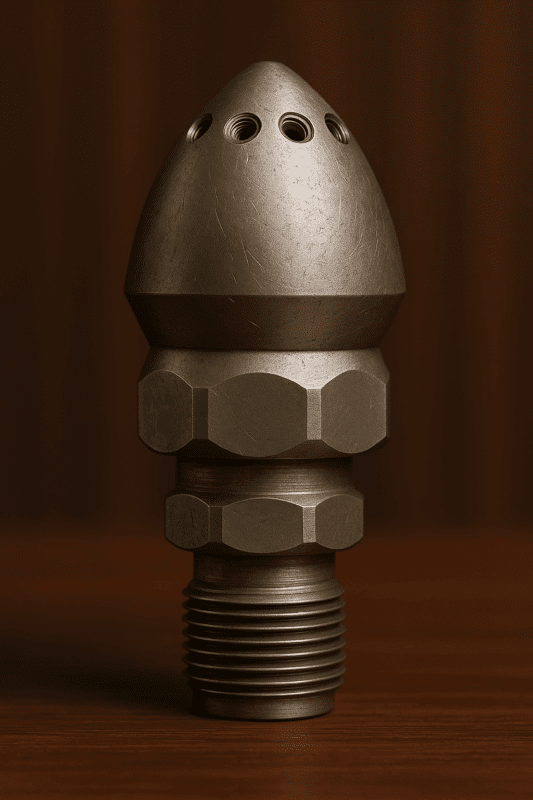

The performance of a hydro jetter hinges heavily on nozzle selection. Each jetting nozzle type is engineered to control both the spray angle and rear thrust, directly affecting the cleaning efficiency and line penetration. For example, penetrating nozzles (like a chisel or rotating cutter) concentrate forward jets at narrow angles (0°–15°) to pierce through obstructions such as grease caps or roots. Flushing nozzles, on the other hand, typically use wider rear jets (30°–45°) to maximize debris evacuation.

Choosing the wrong nozzle can lead to incomplete cleaning, longer job times, or even damage to pipe walls. If you have any questions about your current nozzles contact us our knowledgeable staff are ready to assist you.